What Is 3D Printing?

At its most basic, 3D printing is a manufacturing process in which material is laid down, layer by layer, to form a three-dimensional object. (This is deemed an additive process because the object is built from scratch, as opposed to subtractive processes in which material is cut, drilled, milled, or machined off.) Although 3D printers employ a variety of materials (such as plastic or metal) and techniques (see “How Does 3D Printing Work?” below), they share the ability to turn digital files containing three-dimensional data—whether created on a computer-aided design (CAD) or computer-aided manufacturing (CAM) program, or from a 3D scanner—into physical objects.

Is 3D Printing Even Printing?

Yes, 3D printing can be considered printing, although not as it’s traditionally been defined. The relevant Webster’s definitions of “printing” center on the production of printed matter, publications, or photographs, and producing by means of impression (the application of pressure). Neither definition really fits 3D printing. But from a technological perspective, 3D printing is an outgrowth of traditional printing, in which a layer of material (usually ink) is applied. Usually it’s so thin that there is no noticeable height (though with solid ink printers, it is somewhat thicker). What 3D printing does is greatly extend that height through the application of multiple layers. So it would make sense to expand the definition of printing to include the fabrication of three-dimensional objects in this manner.

How Does 3D Printing Work?

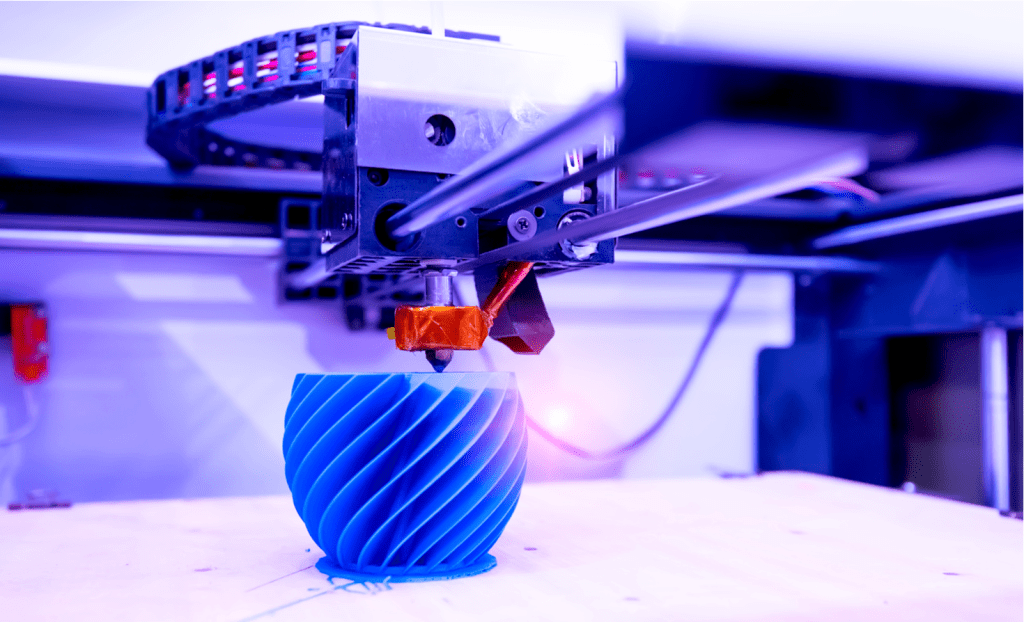

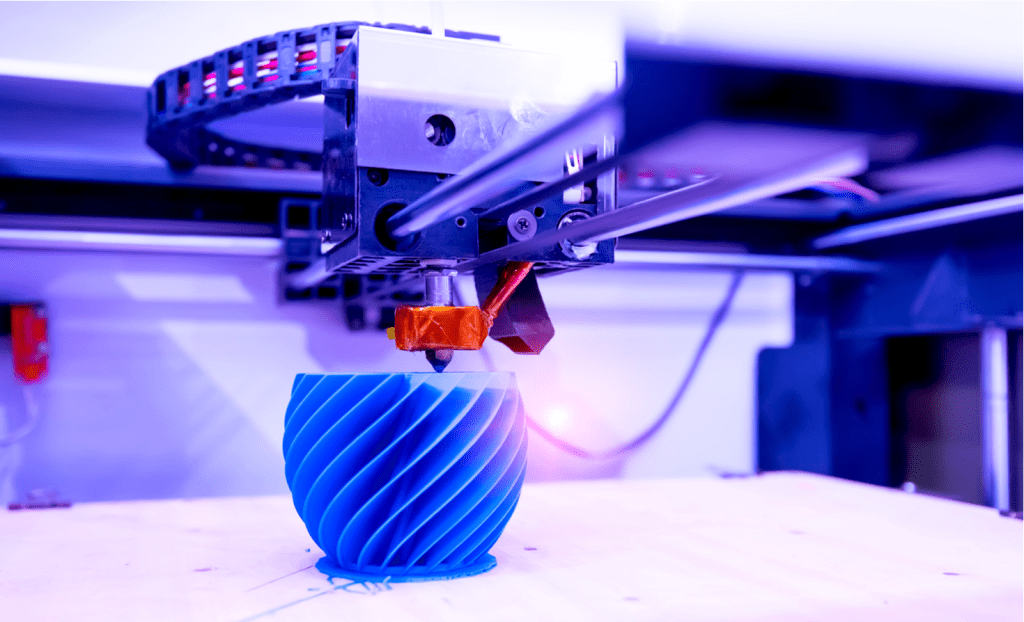

Much like traditional printers, 3D printers use a variety of technologies. The most commonly known is fused deposition modeling (FDM), also known as fused filament fabrication (FFF). In it, a filament—composed of acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), or another thermoplastic—is melted and deposited through a heated extrusion nozzle in layers. The first 3D printers to come to market, made in the mid 1990s by Stratasys with help from IBM, used FDM (a term trademarked by Stratasys), as do most 3D printers geared to consumers, hobbyists, and schools.

Who Invented 3D Printing?

The first 3D printer, which used the stereolithography technique, was created by Charles W. Hull in the mid-1980s. Stereolithography has traditionally been an expensive commercial technique, with machines costing in the five and even six figures, but recent years have seen the advent of desktop professional stereolithography printers costing a few thousand dollars, as well as consumer systems that start well under a grand.

What Can 3D Printers Make?

Designers use 3D printers to quickly create product models and prototypes, but they’re increasingly being used to make final products, as well. Among the items made with 3D printers are shoe designs, furniture, wax castings for making jewelry, tools, tripods, gift and novelty items, and toys. The automotive and aviation industries use 3D printers to make parts. Artists can create sculptures, and architects can fabricate models of their projects. Archaeologists are using 3D printers to reconstruct models of fragile artifacts, including some of the antiquities that in recent years have been destroyed by ISIS. Likewise, paleontologists and their students can duplicate dinosaur skeletons and other fossils. Check out our gallery of simple and practical 3D printer objects.

source:https://www.pcmag.com/news/3d-printing-what-you-need-to-know

Leave a comment